About Graziano™

For nearly half a century, custom-engineered, high-precision Graziano™ gears and shafts have improved the performance, reliability, and durability of final drive components. We support technically demanding and complex vehicle applications by leveraging our engineering expertise to deliver customized crown wheel-and-pinion sets.

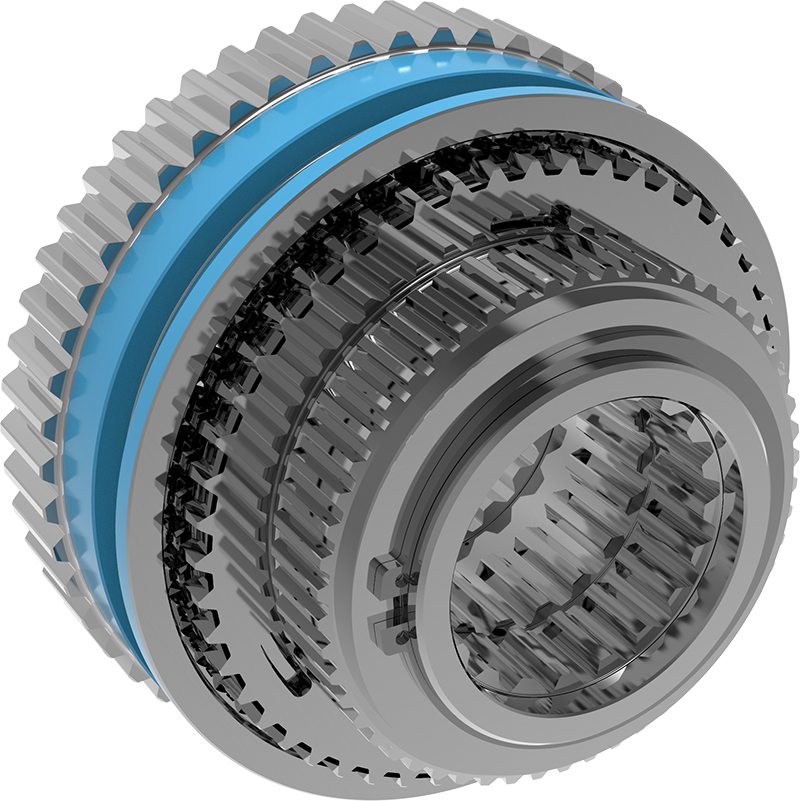

We offer a comprehensive range of heavy-duty synchronizers and advanced shifting solutions that help vehicle and transmission manufacturers address limited engineering resources, while providing operators with superior control, smoother shifting, and improved productivity.

Our in-house design, prototyping, and validation capabilities enable us to develop bespoke drive assemblies for highly specialized applications, ensuring optimal performance and long-term reliability.

Graziano Shifting Solutions™

We are recognized as a worldwide leader in synchronizers and powershift units for agricultural and construction machines with our brand Graziano Shifting Solutions™.

Each type of application for the transmission system is defined in close coordination with the customer since the very beginning of the development. To achieve the best-tailored solution, the company is equipped with state-of-the-art design and virtual validation tools, cutting-edge production technologies, comprehensive analytical instruments, and extensive bench and vehicle tests.

The entire process is supported by a seamless quality-control system.

Product Range

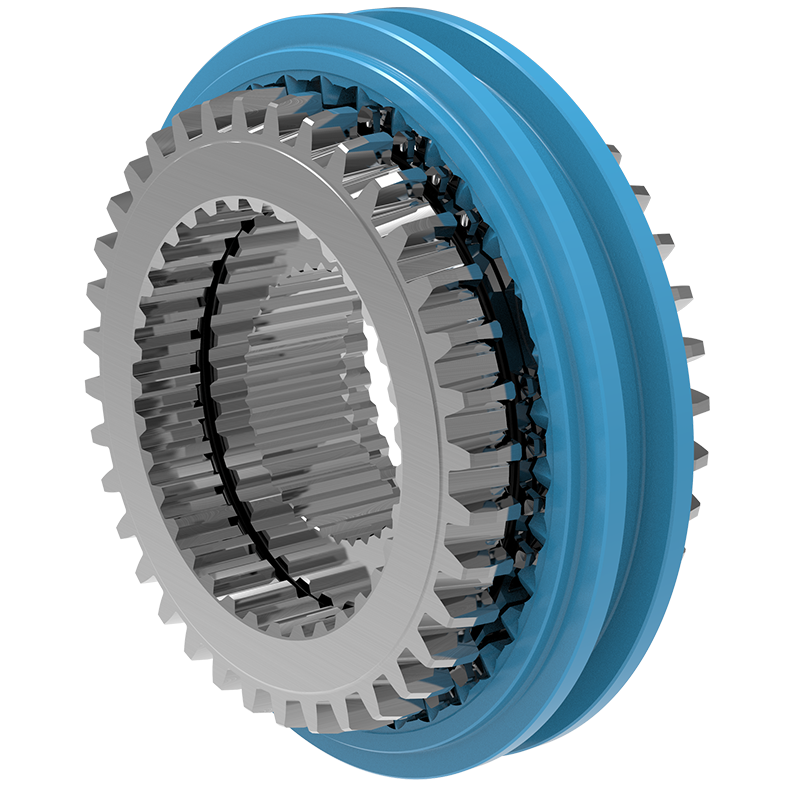

SC 90 / CSS 90 Synchronizer

Robust and reliable with an optimized design for heavy-duty applications

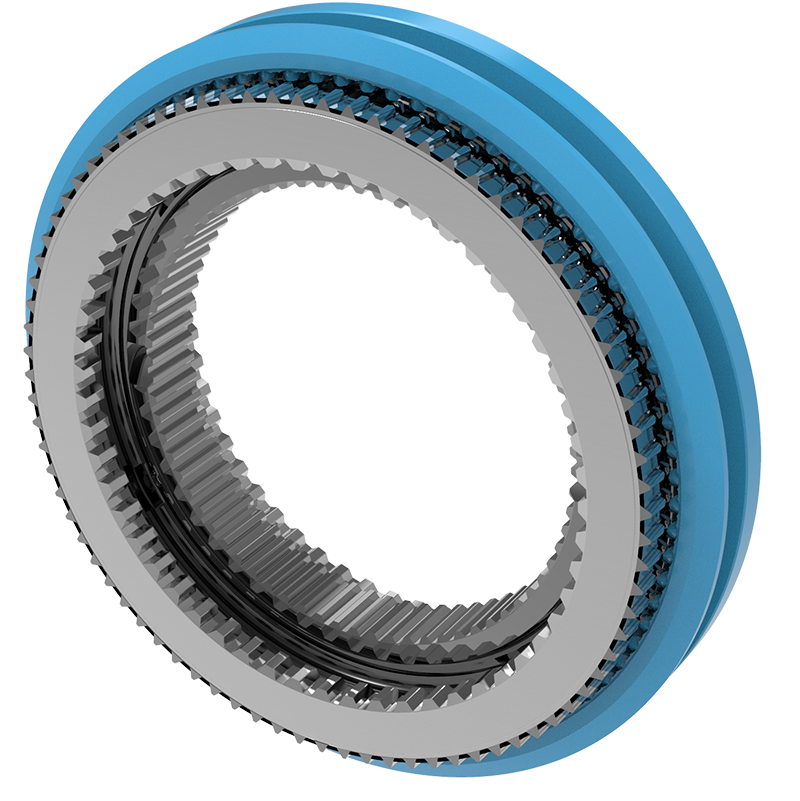

SC 184 Synchronizer

Modular single-or double-cone designs to accommodate a wide range of applications

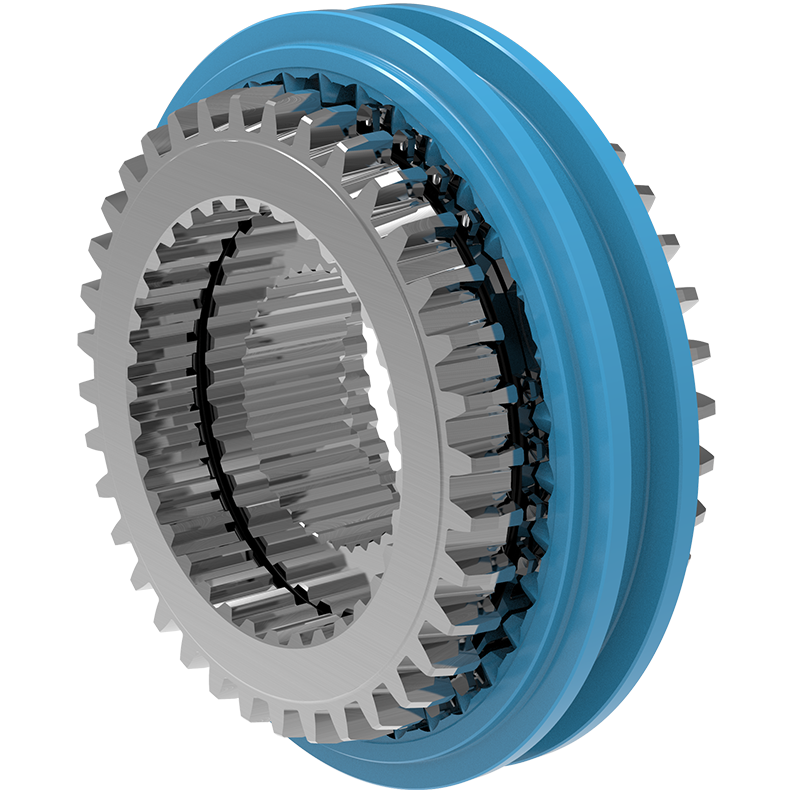

SC 62 Synchronizer

Compact single-cone design ideal for compact transmissions

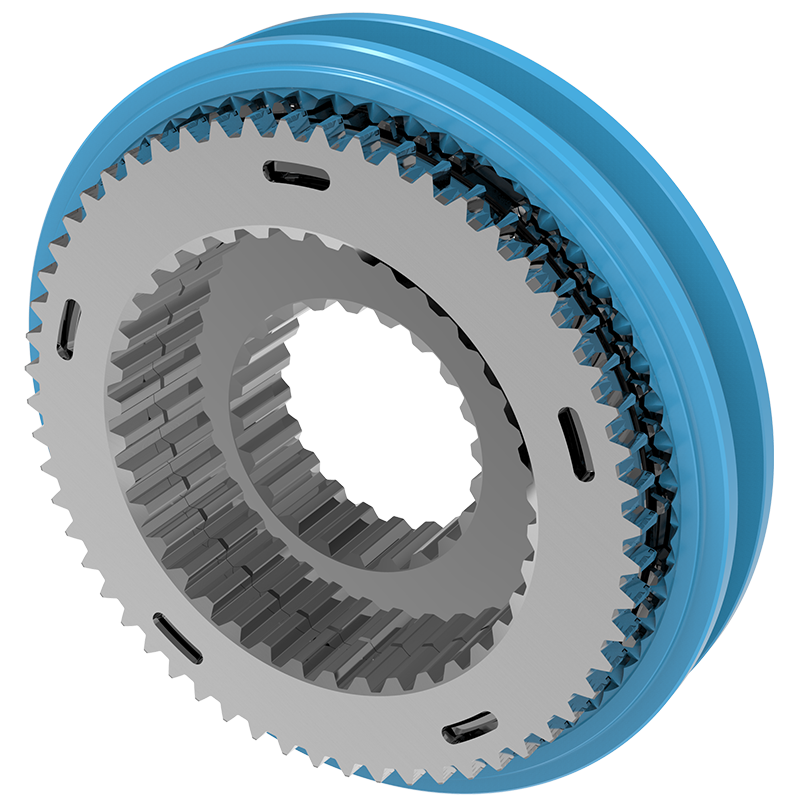

DC 95/100 Synchronizer

Double-cone solution for up to 40% faster synchronization, with higher torque engagement capabilities

TC 102/110/118 Synchronizer

First triple-cone design for the agriculture market. New friction material for heavy-duty applications, plus outstanding torque capability in a compact radial package

Powershift Clutches and units

State of the art technologies available for clutch housings, including flow forming, grob rolling, and broaching with laser or electron-beam welding