Our service department offers a complete support package to for an effective control of the cost of ownership as well to secure the continuity of your operations.

From on-site assistance during initial installation to maintenance and repair during operation – our service will ensure the maximum lifecycle and minimum down time.

Think of:

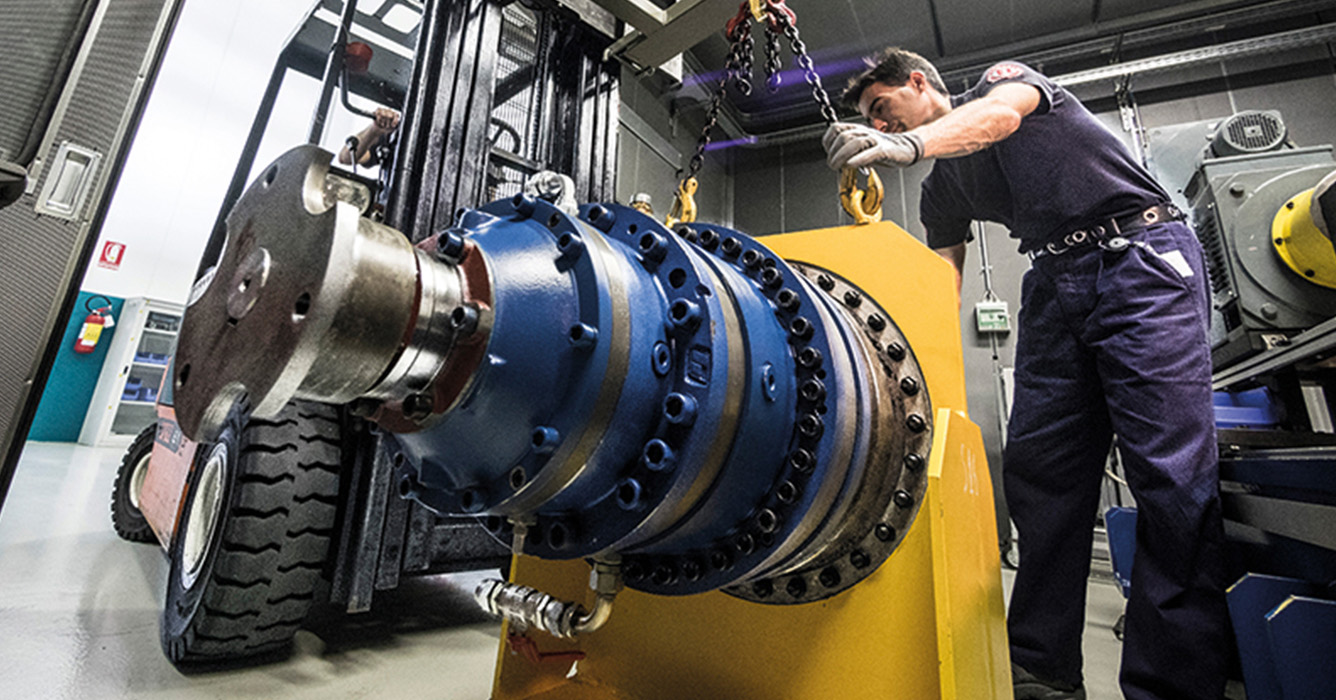

- Installation support

- Maintenance (optional service contract)

- Repair

- Revision

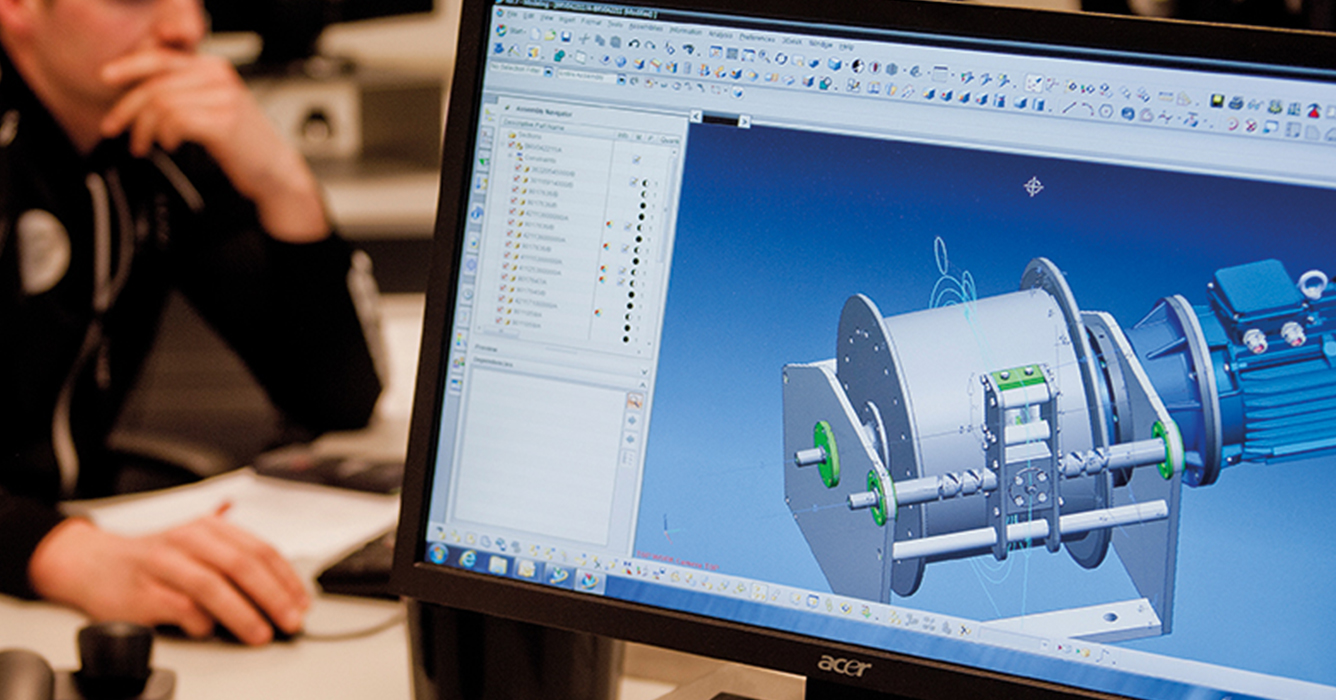

- Problem diagnosing

- Test facility

- Service desk

- Spare parts

- Commissioning